What Does Injection Mold Do?

Wiki Article

What Does Injection Mold Do?

Table of ContentsGetting My Injection Mold To WorkOur Injection Mold PDFsThe Injection Mold StatementsSome Known Facts About Injection Mold.More About Injection MoldMore About Injection Mold

For the mold and mildew supplier and also the element designer, the exact data from the simulation make their work a lot easier. Many thanks to them, lengthy trial-and-error procedures are a thing of the past. Modification loopholes are dramatically minimized. For computer simulations to work and also supply sensible results, the computer systems initially need a lot of input.The exact same can happen if the version to be determined has actually been streamlined a lot on the computer system that it does not reflect fact. Highly specialist injection molding simulation programs consequently include extensive databases acquired from numerous dimensions. Most importantly, this consists of up-to-date material information, which have a considerable impact on the results of the simulation.

Designers or toolmakers should likewise, or also must, be intimately aware of the software. Service-strong software application manufacturers as a result concentrate on user-oriented interface as well as additionally offer easy-to-understand, user-specific as well as interactive training programs. They are also offered to address questions with their knowledge (Injection Mold). This is just how shot molding simulations make an ideal part feasible!.

The Main Principles Of Injection Mold

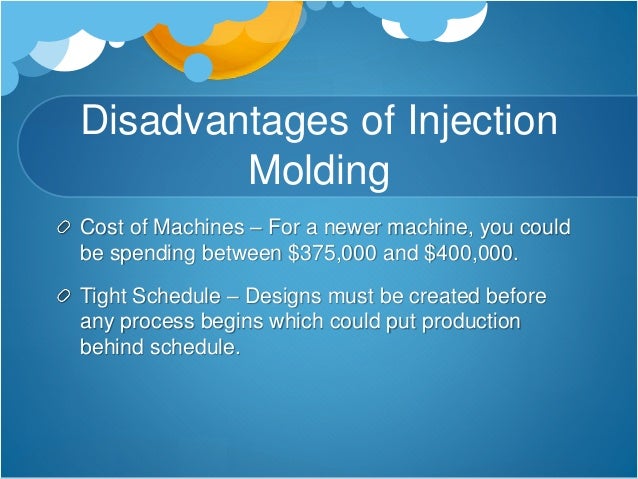

Blog > Advantages & Disadvantages of Response Injection Molding by Rimnetics, posted on Monday, January 24, 2022 Reaction injection molding (RIM) has actually been used to create components for a vast array of different industriescomplex medical devices to building devices. As a lot of product designers know, the production process you select will substantially affect the price, appearances, and also result of your last product.In doing so, you can best identify which procedure will certainly finest fit the details needs of your task. Listed below, we highlight the notable benefits and negative aspects of response shot molding to help maximize your decision-making process. In contrast to other manufacturing processes, such as injection molding, edge molding requires much lower temperature levels as well as stress.

The combination of polyol as well as isocyanate develops a liquid with a consistency comparable to that of electric motor oil, which enables the blend to easily stream right into every space and cranny of even one of the most intricate molds. Thus, no extreme temperature levels or stress are necessary to melt and also create the plastic.

The Basic Principles Of Injection Mold

The reduced pressures and also temperature levels involved in the edge procedure can assist in the encapsulation of a vast array of components, such as antennas, motherboard, magnets, batteries, steel rods, and also threaded inserts. Encapsulation can offer countless benefits, such as improved defense for more vulnerable parts, theft avoidance, as well as lowered parting lines.

Injection Mold Fundamentals Explained

RIM is much more economical when it involves generating bigger partsespecially in smaller production quantities. In enhancement to producing majorities, edge is likewise well-suited for making and also building get rid of complex geometries. Response injection molding differentiates itself with the high level of layout liberty it offers. For instance, edge can create link parts with varying wall surface densities, curves, and also encapsulated parts, to name a few in-demand important site functions.Therefore, RIM is often contacted to produce components for medical gadgets as well as research laboratory equipment. The capability to lower the variety of parting lines on a part is one more benefit provided by the response injection molding process. As we previously specified, edge allows producers to envelop things directly into a part as well as generate bigger, complex parts in an effective as well as affordable manner.

As with any production process, there are certain applications for which response shot molding might not be proper. RIM typically isn't well-matched for parts requiring bigger manufacturing quantities.

Everything about Injection Mold

If your yearly production quantity falls within this array, the considerably lower tooling cost of edge will considerably balance out manufacturing costs. However, given that edge also requires additional ending up as well as post-molding job, it normally has a somewhat higher specific part rate than injection molding. Hence, when you need to generate parts in very high volumes, the higher specific part costs will inevitably exceed the price savings supplied by a more economical device.We wish this guide on the primary benefits and negative aspects of response look at here now injection molding aids you identify whether edge is an ideal method for your production task. If you assume your project might gain from the response shot molding procedure, Rimnetics can help. Rimnetics is North America's leading response shot molding firm for units, cosmetics real estate, structural parts, encapsulation, and over-molding.

Discover a lot more concerning the high-grade RIM services that Rimnetics provides; contact us today.

Rumored Buzz on Injection Mold

To aid, we have actually really just set out the advantages and drawbacks to consider. Please understand, however, that the adhering to standards use to what we would consider to be standard shot moulding (quantities of 100,000+) and might appear at first glance to be rather expensive if you are wanting to develop an item with numbers out of this standard.In addition, we are experts in making shot moulding far extra cost reliable for much lower amounts of parts than is a lot more typically anticipated. The result is a mould tool that mirrors the requirement and also opens up an exciting choice to generate high quality, yet reduced quantity components.

Report this wiki page